Preventing breakdowns with Total Productive Maintenance “TPM” and generating the right behaviours to create ownership can leave many manufactures playing catch-up. When equipment or processes breakdown everyone is affected, most of the time we know what’s caused it but are we taking the time to prevent these breakdowns from happening in the first place?

When lines fail to produce costs go up – labour becomes more expensive, energy costs increase, production schedules go out the window and the value of production goes down, now were firefighting right !

Working in a manufacturing environment is tough, time and money are limited, the pressure is always on to meet orders and quality expectations are always high. If your still reading at this point you’re saying to yourself “that sounds like where I work”, you’re right to say that as manufacturing is similar all around the world. So why do some manufactures excel while others firefight?

Preventing breakdowns is a long game and requires a strategic perspective to realize the up time benefits, there are many approaches adopted by manufactures to increase up time often with varying results. My experience is that two approaches when used in combination build new capability and deliver sustainable results when implemented correctly, they are Total Productive Maintenance (TPM) and Maintenance Planning.

TPM is a culture that empowers teams to take ownership of equipment through the development of Operator Asset Care (OAC) capability, this capability says – we don’t accept breakdowns, we don’t accept defects and we don’t accept risk, OAC encourages production, maintenance and related departments to work together to resolve “Abnormal Conditions” and eliminate re occurrence in an environment that builds the correct relationship between operators and equipment to create ownership.

Generating the right behaviours to create ownership can be a challenge but through participation in positive action we can get there as long as we can respond and listen to what operators say to us “If you want me to do something new for you, can I ask that you”

- Involve me in the development of new ways of working.

- Use my ideas to improve performance and culture.

- Show me the results of our actions.

- Provide me with the necessary skills to work in a new way.

- Schedule my improvement work in the same way you do production.

There are logical routes to setting standards for cleaning, lubrication, inspections and problem prevention. It’s this development of standards that builds reliability and where you have reliability you have predictability, predictability to know that your production schedule will be met right first time.

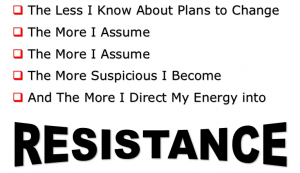

What Happens when we don’t communicate plans to change ?

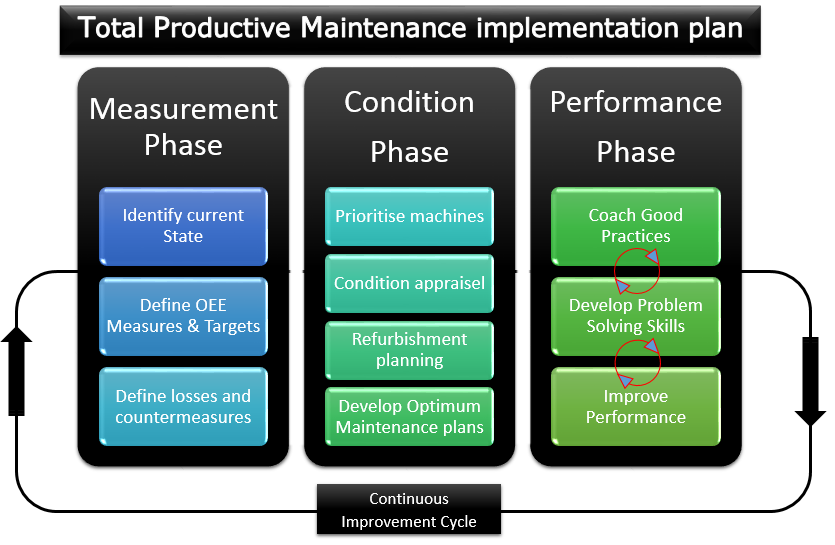

Developing operator asset care capabilities is a straightforward process, that’s not to say that organizations can’t stumble and fall. Preparing a site to walk the walk of TPM requires change throughout the organization, changes that are made without communication will be resisted; that’s human nature but with the correct implementation plan, risks that would normally threaten an initiative like TPM can be mitigated. For TPM to be successfully implemented you need to be strategic and have a plan to ensure successful integration of new activities into “the way we do business here” please refer to fig 1. TPM Implementation.

Figure 1 TPM Implementation- Adapted from Peter Wilmott’s 9 step model

Figure 1 TPM Implementation- Adapted from Peter Wilmott’s 9 step model

Preventing breakdowns with TPM and

Maintenance Planning and Scheduling

Complimenting TPM with maintenance planning and scheduling makes a lot of sense, I will try to explain why. If I’m an operator on a line where we have just rolled out TPM, I am completing cleaning, lubrication and condition based inspections regularly and doing my best to prevent unplanned events, but none of my improvement requests are getting completed, some or none of the issues I see are getting fixed! – I will lose interest quickly. With maintenance planning and scheduling work flows we close this loop and get continuity and velocity into the request/complete work cycle, this energizes teams, increases reliability and increases the count of completed jobs done-everybody wins.

Preventing breakdowns with TPM and

Performance Management

Recognizing the importance of keeping score and playing to position really makes sense when you’re looking to implement new ways of working or if you seeking new levels of performance. Getting your teams ready to play to position and participate in score keeping is a relatively easy endeavour with new technologies to automate the data collection and dashboards to communicate this data in real time on the shop floor. Key performance indicators (KPI’s) can be either leading or lagging so it’s important to know the difference in terms of OEE and Maintenance planning as prevention is definitely better than cure when we’re talking about preventing unplanned events like equipment breakdowns or reworking product.

We really hope you have found this article of value and that it has inspired you to learn more about preventing breakdowns, just remember the hardest part of any journey is getting started but once begun you will learn it’s an enjoyable and rewarding experience that can improve your organization’s culture and performance in a very positive way.

Operator Asset Care helps you operate at your optimum.