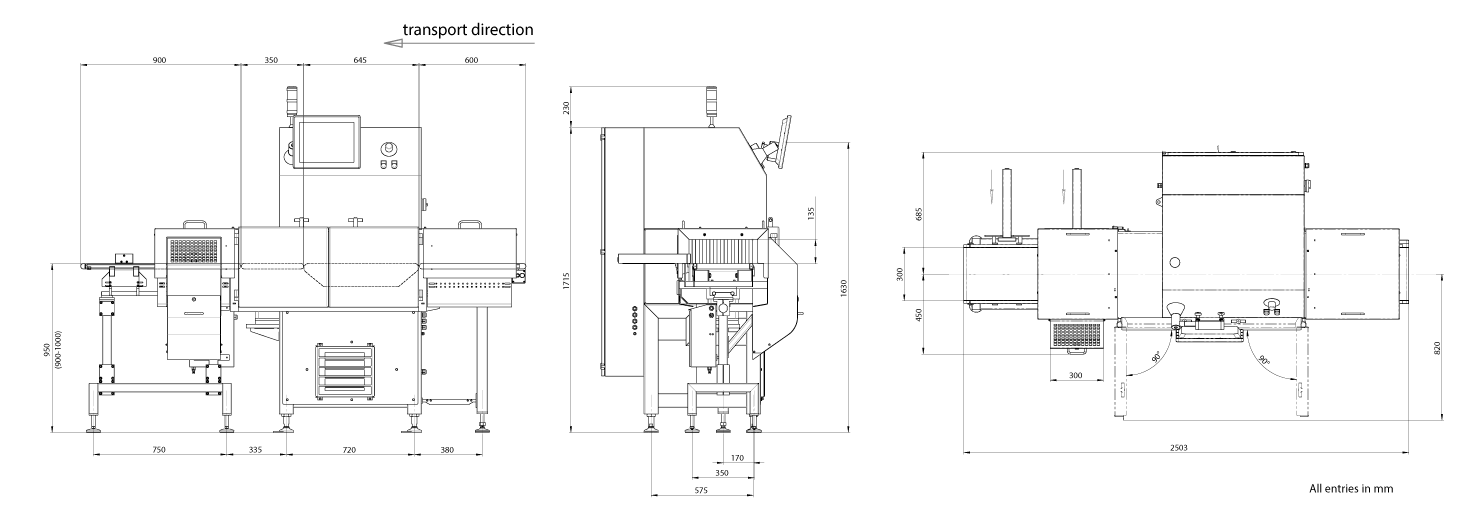

X-RAY INSPECTION AND CHECKWEIGHER IN A SINGLE COMPACT UNIT

The W series is available as a single or dual-track model both are very successful – either with or without the curtain for radiation protection. The model sans curtain provides highest throughput with rates of up to 300 pieces per minute per track, including extremely light products. The x-ray inspection system is designed to allow for a tool-free exchange of all conveyor belts, plus the easy to handle housing makes it quite straightforward to clean the system. The product chamber is completely separated from the drive system components. All of the X-ray inspection systems share a common interface that is easy to use and familiar amongst the operation team regardless of what model you may deploy on each production line. Similar to our in motion checkweighers. Each system includes a 15” colour screen (TFT) that is touchscreen enabled. The W series is designed to meet IP65 protection and manufactured of full stainless steel construction, employing a a balcony design and sloped surfaces that, when used together with the C-shaped and weldless product chamber allow for thorough cleaning and sanitation quickly and easily. All scanners meet the most stringent standards of hygiene.

KEY FEATURES

- X-ray scanner and checkweigher in one unit

- Flexible component design

- Available as single or dual-track system

YOUR BENEFITS

- X-ray scanner and checkweigher for maximum product safety

- Easy to operate central user interface

Specifications

| X-ray type | Metal-ceramic tube with integrated water cooling system orair-cooled monoblock | ||

| X-ray output | up to 600 W, depending on type (infinitely variable) | ||

| X-ray sensor | Long-life camera technology with 160 μm resolution | ||

| Scanning width | from 300 to 600 mm1) | ||

| Scanning speeds | up to 120 m/min with up to 300 products per track | ||

| Product storage | 100 products, expandable | ||

| Display | 15“ colour TFT with touchscreen (19“ optional) | ||

| Working height | 750-850 mm, 800-900 mm, 850-950 mm 2) | ||

| Weight | approx. 500 kg | ||

| Hygienic design | Complete stainless steel model (1.4301), easy to clean product area; built-in drive technology | ||

| Ambient conditions | +5°C to +40°C, relative humidity 30% – 85% | ||

| Protection class | IP65 | ||

| Power supply | 230 V, AC/50Hz, 2.5 kVAConnection with separate, 16 A fuse power line | ||

| Weighing technology | Gross weight range | Max. preload | Min. calibration value |

| Single track | 750 – 7,500 g | 4,000 – 15,000 g | 0.1 g |

| Dual track | 750 – 7,500 g | 4,000 – 15,000 g | 0.1 g |

| Max. output3) | 300 ppm | ||

| Certification | DE-08-MI006-PTB028 (MID) | ||

| Standard deviation (1s)3) | > 50 mg | ||

- Wider models available by request

- Other working heights by request

- Dependent on product form, product behaviour, transport speed, and local conditions

INNOVATIVE IMAGE PROCESSING SOFTWARE

We build state-of-the-art image processing software used in our X-ray scanners. Developing the softwae inhouse means we are completely independent to external software vendors, in tiurn allows us to respond quickly to your individual applications by creating a custom solution for you.