SERIALIZATION OF BUNDLES AND SETS

The Bundle Pack is the first level of product aggregation and allows for the groupoing of in=dividual cartons and or bottles into sets. These newly formed bundles are issued a serialization number representing the individual items that form the bundle. Bundles are received automatically from an upstream bundler or can manually introduced to the station. The system applies a label to the newly formed bundle and then reads and assigns the individual product sreialization codes to the bundle unqiue identiifcation code. Regardless of whether the packaged sets are rounded by stretch wrapping, shrink wrapped, or fully overwrapped, they can be reliably and safely read by means of the optional UV camera.

KEY FEATURES

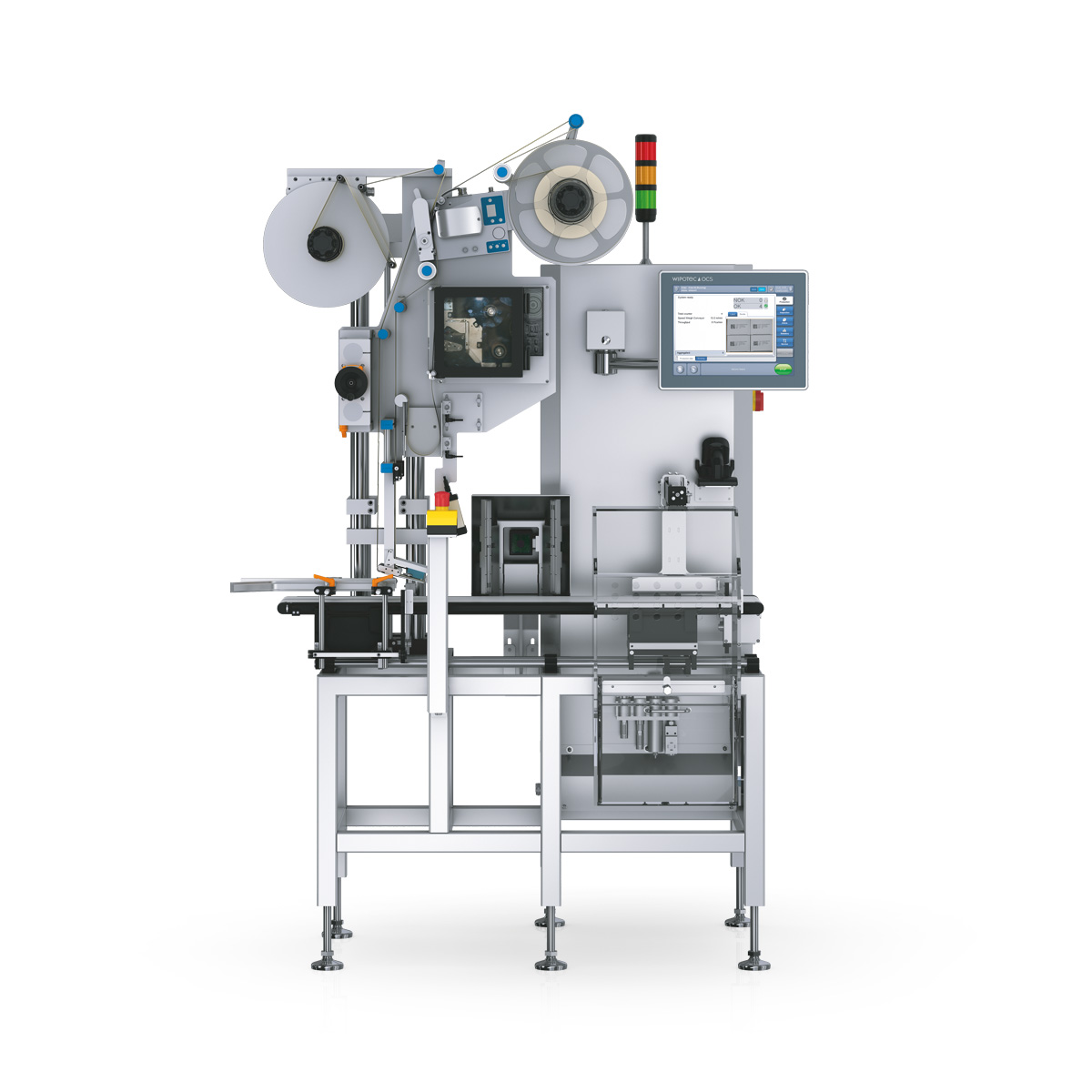

- Fully integrated label printer and applicator unit, incl. camera control

- High performance TQS VIO 2 camera for precise code verification

- Handheld scanner for manual read in and changing aggregation hierarchies

- Reliable discharge by means of the traction pusher

- Large 15″ with touchscreen display and intuitive control menu (19″ optional)

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Camera mounts front and back (optional)

- Tool free format change

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- Space saving design facilitates integration in existing lines

- High throughput rate (up to 75 pcs/min, 30 pcs/min standard) enables significant increase in productivity

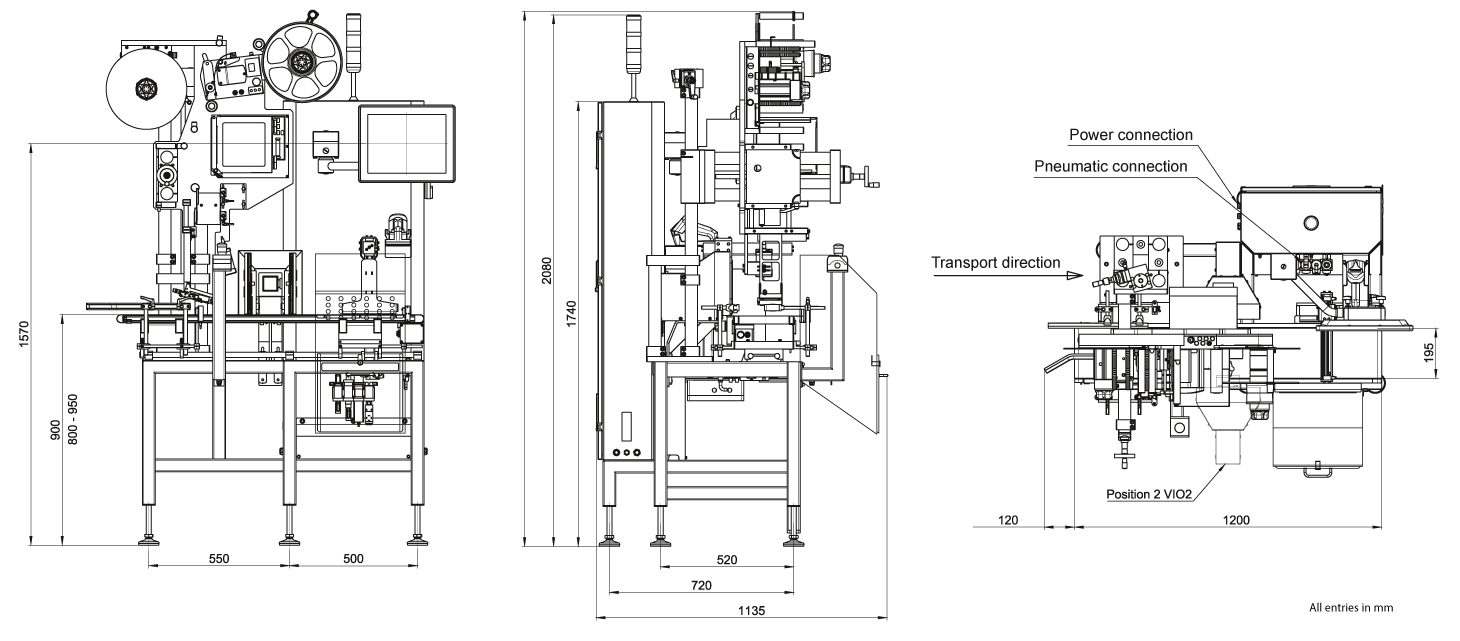

Specifications

| Max. output | up to 75 pcs/min (30 pcs/min is standard) 1) |

| Rated voltage | L1/N/PE 230 V / 115 V |

| Rated frequency | 50/60 Hz |

| Power capacity | approx. 0,8 kVA |

| Compressd air supply | approx. 6 bar 16 Nl/min Quality class 1/4/1 per DIN ISO 8573-1 |

| Protection class | IP54 4) |

| Stainless steel | V2A/AISI 304 |

| Working height | 700-850 mm, 800-950 mm, 900 -1.050 mm 2) |

| Bundle dimensions (L × B × H) | min 300 x 200 x 220 mm 3) |

| Workable kinds of code | 1D Barcodes, 2D Codes |

| Weight | approx. 210 kg |

FOOTNOTES:

- Depends on set size, number of cartons included, and transport conditions

- Water jet from above

- Other working heights by request

- Other carton dimension on request

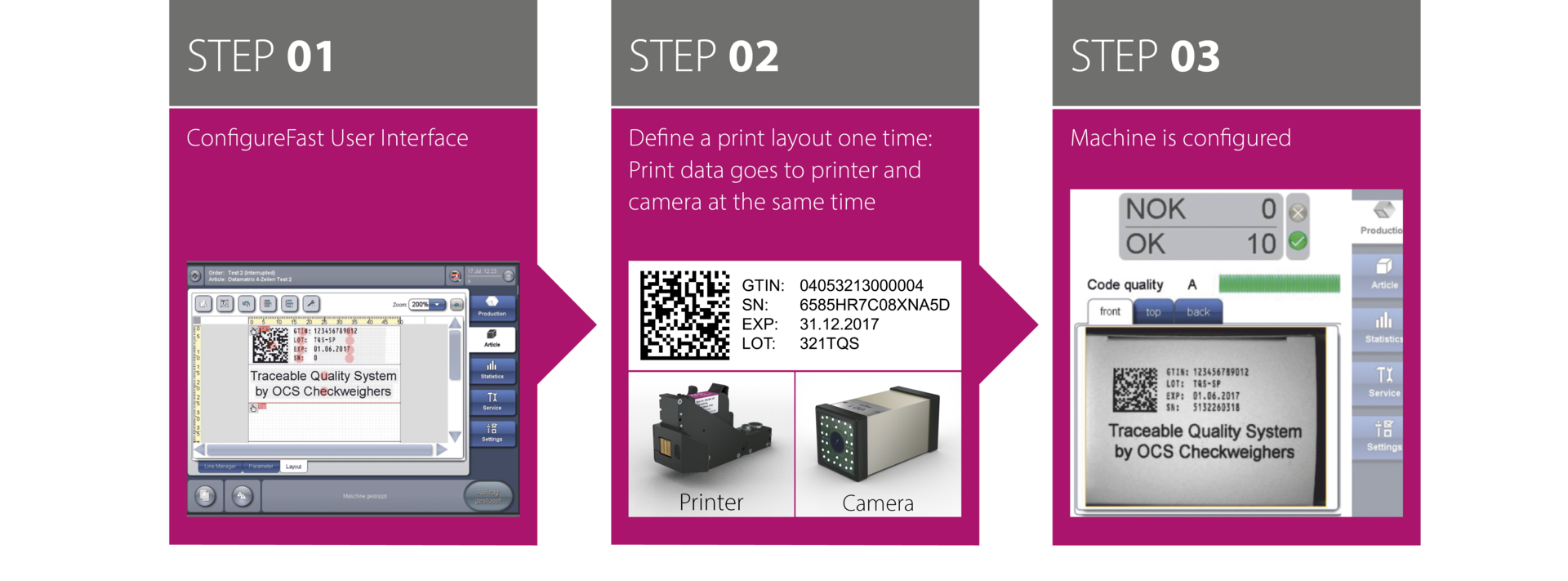

INTUITIVE CONFIGURATION SOFTWARE

Cofigure Fast controls the transport system, coding unit, camera, checkweigher and labeller all from a single HMI interface. As an operator this means easy, quick set-up translatimg into short changeover times on product change. Work with one interface instead of multiple seperate HMI’s, plus no product training is required for your camera system when introdcing new products.

Active members in both the GS1 Germany and Open SCS Working groups with a focus to support standadrdization promoting open and flexible systems ensuring choice for clients.

Dependable expert services, customized to your needs. Factory trained technicians, along with remote service capabilities, we will help you to design a plan that best serves your needs.