CASE PACK SERIALIZATION

The Case Pack station provides the ability for semi-automatic aggregation of manually repacked folding boxes. It allows you to easily assign units from a lower level (folding box or bundle) to the next packaging level the shipment carton. The operator is stepped through each phase and places the packaged units layer-by-layer in the shipment carton. Each completed layer is then captured and verified from above by the fully integrated camera. The camera automatically adjusts to the correct height for packing in order to always ensure the proper focus distance. After the predetermined number of layers and units has been achieved the aggregation level is completed and a label is automatically generated. In addition, the Case Pack station also manages the next packaging level (shipment cartons loaded on pallets). The aggregation of the pallets can be managed in parallel by the optional Pallet extension module. In this acse the operator takes advantage of our software deployed on he mobile scanner to complete the Pallet aggregatuon step.

KEY FEATURES

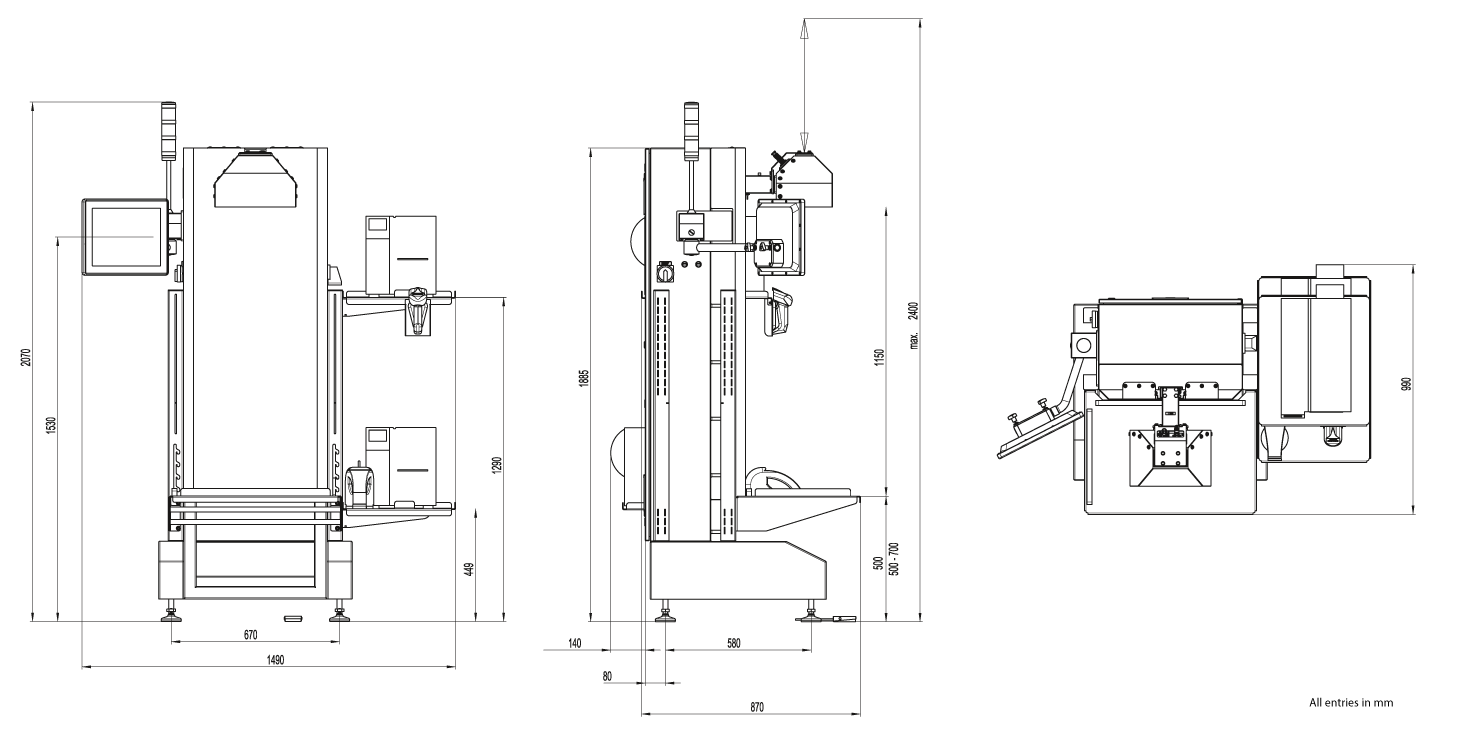

- Industrial scale labeler on adjustable height table

- State of the art camera for multicode-reading from above and fully integrated operator guidance

- Large 19″ with touchscreen display and intuitive control menu

- Ergonomic design with adjustable product table height

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Weighing platform (optional)

- Tool free format change

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- Safe and reliable aggregation of every single product

- Greater value from one machine for the aggregation of shipment cartons and pallets (optional)

Specifications

| Max. output | Manual product feed by operator |

| Rated voltage | L1/N/PE 230 V / 115 V |

| Rated frequency | 50/60 Hz |

| Power capacity | approx. 0,8 kVA |

| Protection class | IP54 4) |

| Stainless steel | V2A/AISI 304 |

| Package dimensions (L × B × H) | min 10 x 40 x 10 mm to max 600 x 400 x 400 mm 1) |

| Workable kinds of code | 1D Barcodes, 2D Codes |

| Weight | approx. 160 kg |

FOOTNOTES:

- Other package dimensions by request

- Water jet from above

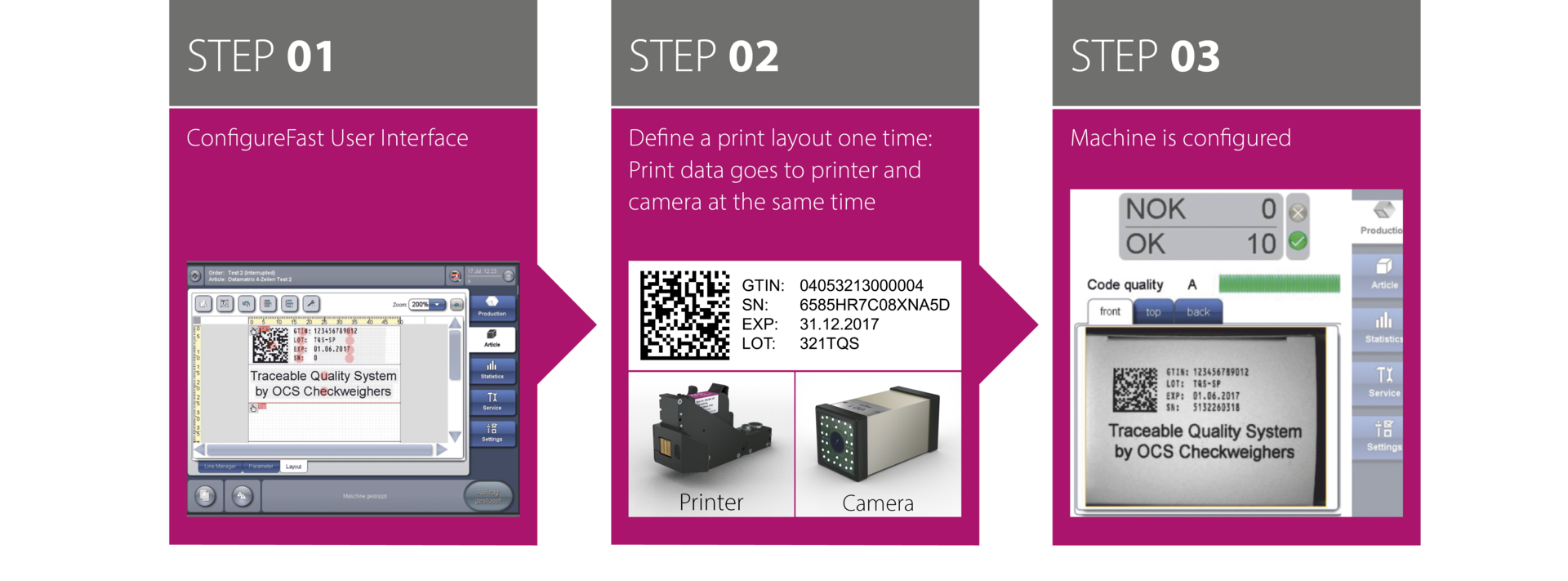

INTUITIVE CONFIGURATION SOFTWARE

Cofigure Fast controls the transport system, coding unit, camera, checkweigher and labeller all from a single HMI interface. As an operator this means easy, quick set-up translatimg into short changeover times on product change. Work with one interface instead of multiple seperate HMI’s, plus no product training is required for your camera system when introdcing new products.

SUPPORT FOR STANDARDIZATION

Active members in both the GS1 Germany and Open SCS Working groups with a focus to support standadrdization promoting open and flexible systems ensuring choice for clients.

GLOBAL SERVICE

Dependable expert services, customized to your needs. Factory trained technicians, along with remote service capabilities, we will help you to design a plan that best serves your needs.