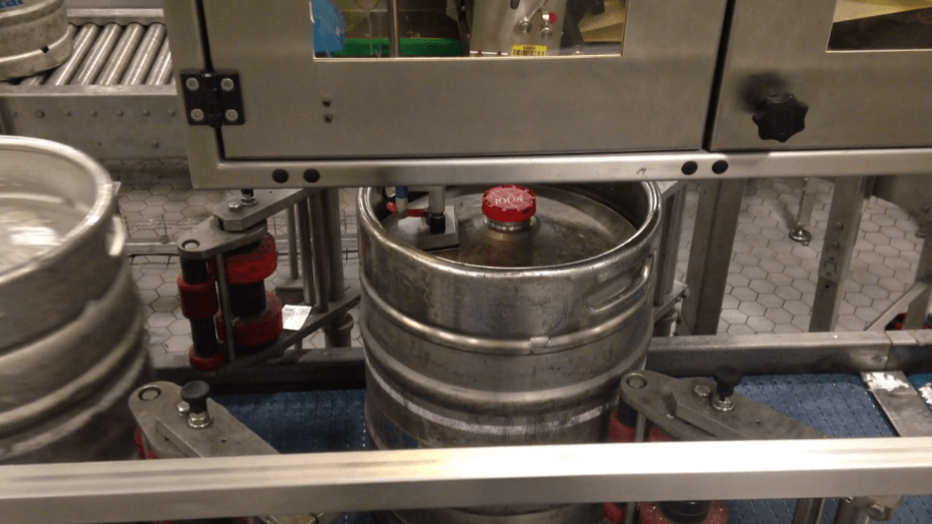

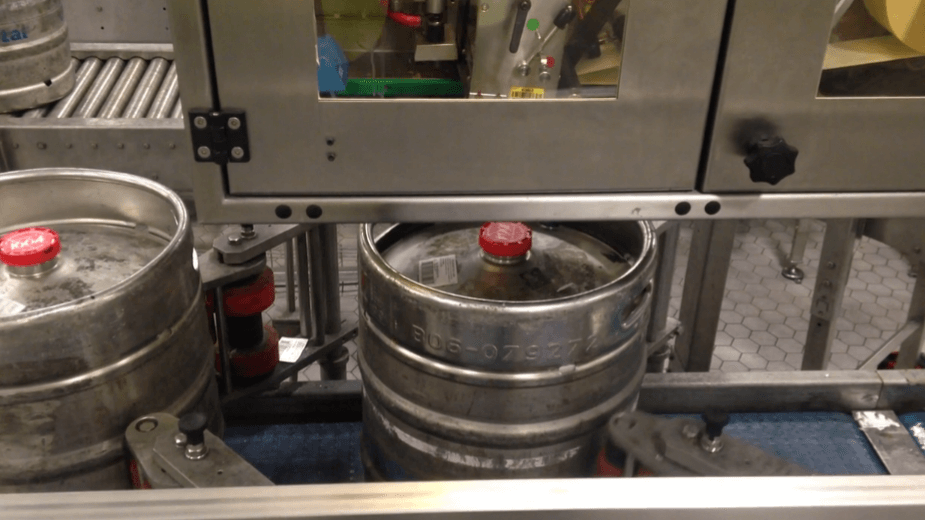

KEG CASK AND DRUM LABELING

The keg and cask labeling solutuon is designed for continuous use in a brewery environment. Deesigned and manufactured in Germany from 90% inhouse components our print and apply labeling machine is certain to provide years of performance. Capable of printing and applying up to 16 labels per minute each container can be assured to have a label with traceable production details as it ravels throughout the supply chain.

KEY FEATURES

- Label 16 kegs/casks per minute

- Direct thermal or thermal transfer

- Label applied from top

- Label sizes 15mm x 15mm to 100mm x 150mm

- Z-mode and S-mode emulation supported

- Standalone setup or integrated installations

- Comprehensive software suite

YOUR BENEFITS

- Designed to operate in brewery environment

- Ease of integration into existing production line

Specifications

| Type | Tamp, Tamp with blow assist |

| Possible label positions | Side |

| Number of labels per product | 1-3 |

| Thermal transfer capability | Yes |

| Direct Thermal capability | Yes |

| Prnt resolution | 203 dpi / 300 dpi |

| Max Print width | 156mm |

| Max width of backing paper | 160mm |

| Max ribbon roll length | 1200m |

| Max label roll outer diameter (O.D.) | 350mm +/- 5mm |

| Label core diameter | 76 / 152mm |

| Minimum label gap |

|

| Pad sizes (WxL) | |

| Max distance to product | 1200mm |

| Typical labels printed and applied | 120/hr / 240/hr |

| Input air pressure | 6 bar, ½” BSP fixed, oil & water free |

| Dimensions (LxHxW) | 670mm x 605mm x 365mm |

| Print languages | Zebra, SATO (emulated) |

| Interfaces | Serial (RS-232, RS-422), Ethernet, Wireless Ethernet, Profibus, Digital I/O |

| Certifications | CE (EU), UL (508)1 |

FOOTNOTES:

- Optional offering

VARIOUS APPLICATOR OPTIONS

From a standard tamp apply to a dual head applicator applying two labels simultaneously we have the expereince to ensure yoir products are labeled correctly, precisely each and every time. We have applied labels to uneven products, round shaped products, non contact application, around the corner (corner warp labels), swing arm for front and / or back label applyshrink wrap prodcut, even from below or above to name a few.

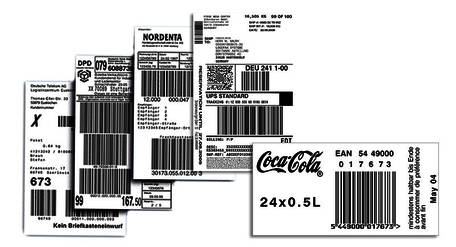

Offering thermal tarnsfer and direct thermal labels in a variety of materials; paper, coated, poly, etc..In addition we offer custom labels shape, peel offs, size, pre-printed, colour, adhesive options. Pairing our transfer labels with high quality ribbon provides a turn-key solution. We even produce custom roll sizes to match exactly the length of your ribbon, so you only need to stop your labeller once and change both at the same time!

Dependable expert services, customized to your needs. Factory trained technicians, along with remote service capabilities. Taking advantage of one of our preventive maintenance programs will help ensure your labeler performs at its’ optimum. Contact us today we will galdly help you to design a plan that best serves your needs.

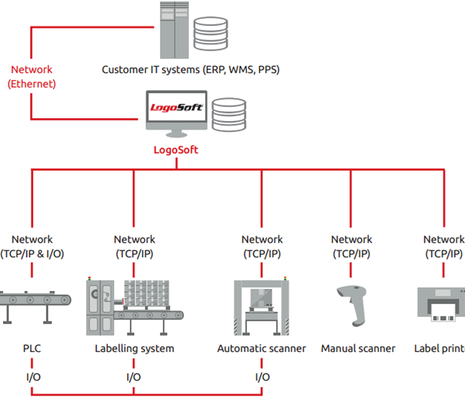

SOFTWARE

MIddleware - ERP | WMS Connection

Centralized data administration

Elimination of manual, per unit changeovers

Label Design Software

Create templates and re-use layouts

Data linking supported

Remote Connect

Push data updates and perform backups

Deliver updates to multiple machine in paralell