INSPECTION STANDING PRODUCTS FOR IMPURITIES AND FILL LEVEL

The S series models follow a modular design that allows for space-saving integration with any existing production line. The sideview scanner reliably inspects cans, bottles, mixed packaging materials, paper, or plastic containers. Supports either a belt or a chain conveyor both can pass through the scanner’s housing.

All of the X-ray inspection systems share a common interface that is easy to use and familiar amongst the operation team regardless of what model you may deploy on each production line. Each system includes a 15” colour screen (TFT) that is touchscreen enabled. The W series is designed to meet IP65 protection and manufactured of full stainless steel construction, employing a a balcony design and sloped surfaces that, when used together with the C-shaped and weldless product chamber allow for thorough cleaning and sanitation quickly and easily. All scanners meet the most stringent standards of hygiene.

KEY FEATURES

- Flexible component design

- Checks standing products like cans, bottles, PVC containers

- Compact design

- Integrated conveyor systems

YOUR BENEFITS

- The broadest inspection for maximum productivity

- Compact design for easy integration

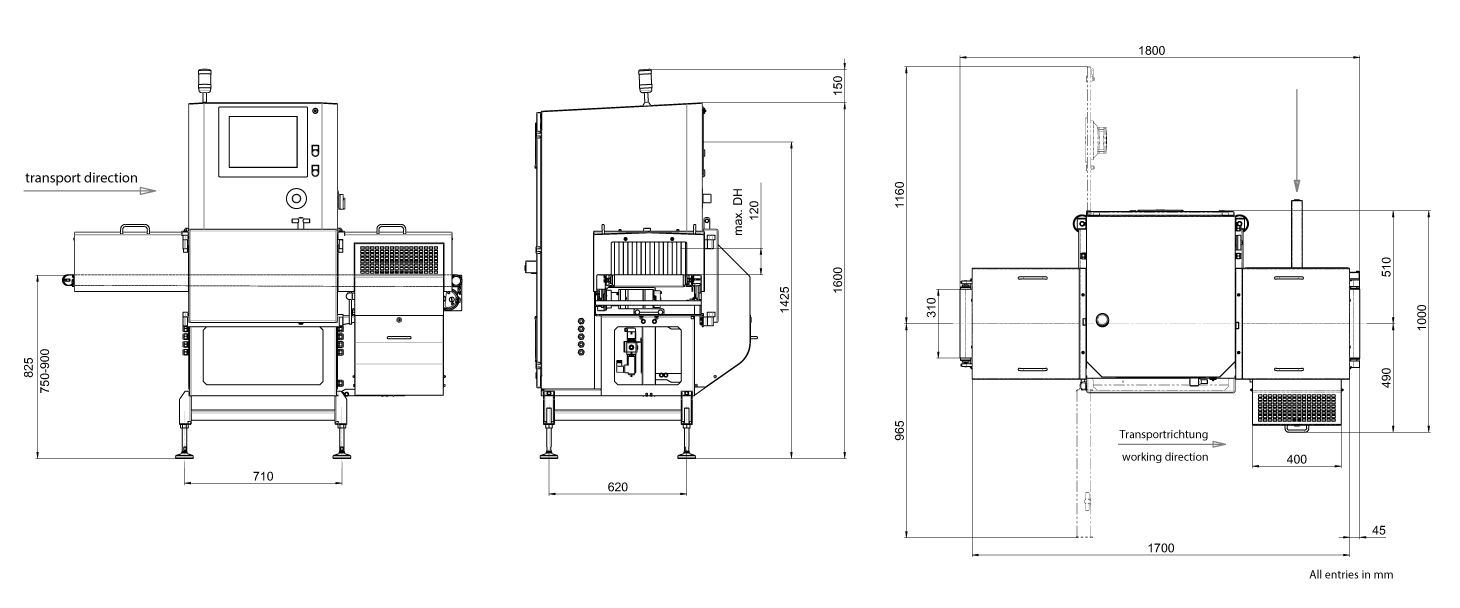

Specifications

| X-ray type | Metal-ceramic tube with integrated water cooling system orair-cooled monoblock |

| X-ray output | up to 600 W, depending on type (infinitely variable) |

| X-ray sensor | Long-life camera technology with 160 μm resolution ordiode array technology with 0.4 mm resolution |

| Scanning width | 400 mm1) |

| Scanning speeds | up to 120 m/min |

| Product storage | 100 products, expandable |

| Display | 15“ colour TFT with touchscreen (19“ optional) |

| Working height | 750-850 mm, 800-900 mm, 850-950 mm2) |

| Weight | approx. 500 kg |

| Hygienic design | Complete stainless steel model (1.4301), easy to clean product area, built-in drive technology |

| Ambient conditions | +5°C to +40°C, relative humidity 30% – 85% |

| Protection class | IP65, IP69K3) |

| Power supply | 230 V, AC/50Hz, 2.5 kVA Connection with separate, 16 A fuse power line |

FOOTNOTES:

- Wider models available by request

- Other working heights by request

- By request

INNOVATIVE IMAGE PROCESSING SOFTWARE

We build state-of-the-art image processing software used in our X-ray scanners. Developing the softwae inhouse means we are completely independent to external software vendors, in tiurn allows us to respond quickly to your individual applications by creating a custom solution for you.

CONFORMANCE TO STANDARDS

The suite of X-ray inspections systems provide conformity with various quality and food saftety standards such as HACCP, BRC or IFS and a number of others

Dependable expert services, customized to your needs. Factory trained technicians, along with remote service capabilities, we will help you to design a plan that best serves your needs.