SERIALIZATION WEIGHT INSPECTION TAMPER EVIDENT LABELLING OF INDIVIDUAL CARTONS

Taking our Single Pack solution and adding a weighing and tamper evident labelling for both side or top and bottom provides another level of automation within our Total Quality System (TQS) solution portfolio. Serialize each carton, seal each flap, then inspect your codes, verify flap closures and sort product based on a predetermined set of rules. Ensure your country-specific labels or instruction inserts, also referred to as vignettes are applied by way of compact labelling units. The system can alternatively be configured with optional thermal transfer printers to print in-line batch or serialization data. What this means for you: All foreseeable regulations regarding serialization worldwide can be met with just one space-saving and user-friendly machine.

KEY FEATURES

- Highly precise product transport

- Fastest configuration with Configure Fast

- Tamper Evident seals

- Flexible print head / camera mounting position

- High-tech Weigh Cells from Wipotec for high precision weighing

- Large 15” touchscreen display and intuitive control menu (19” optional)

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Tool free format change

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- Compact, high-tech, multi-functional unit for optimal productivity

- High throughput rate of up to 600 pcs/min (300 pcs/min is standard)

- Maximal integration flexibility through modular design

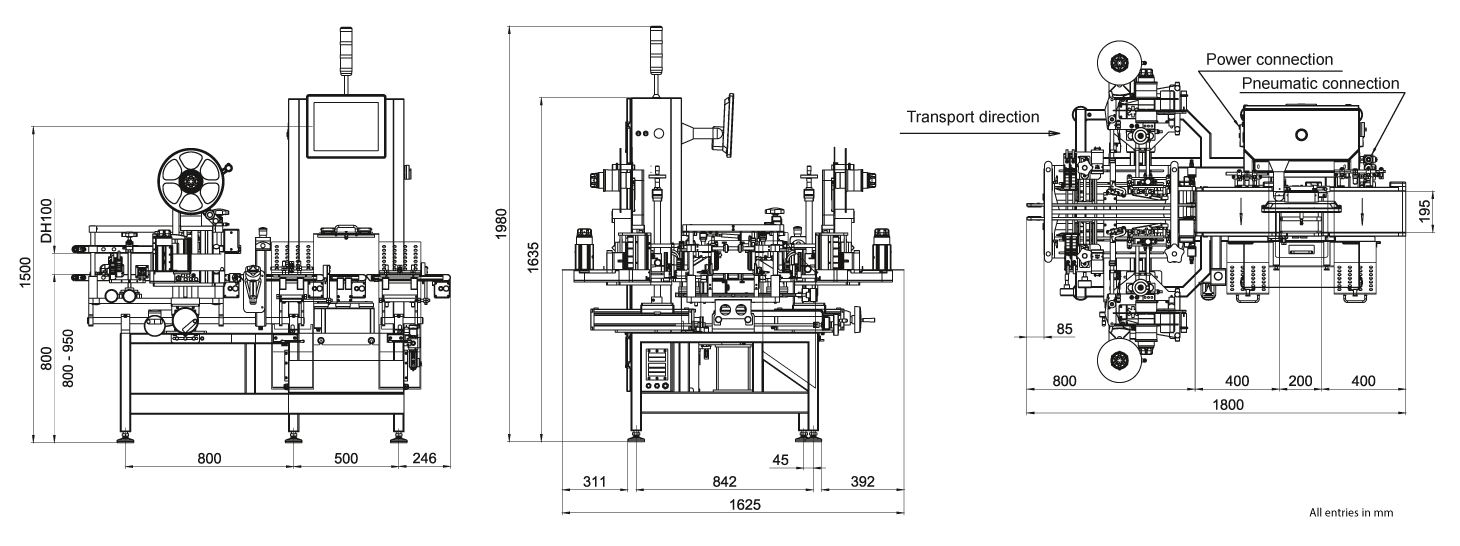

Specifications

| Max. output | up to 600 pcs/min (300 pcs/min is standard) 1) |

| Weight range | 750 g |

| Display value (d) | 0,01 g |

| Calibration value (e) | 0,1 g |

| Standard deviation (1s) | from 50 mg 2) |

| Rated voltage | L1/N/PE 100-240 V |

| Rated frequency | 50/60 Hz |

| Power capacity | approx. 0,8 kVA |

| Compressed ait supply | approx. 6 bar 16 Nl/min, Quality class 5/3/ per DIN ISO 8573-1 |

| Protection class | IP54 3) |

| Stainless steel | V2A/AISI 304 |

| Working height | 700–850 mm, 800–950 mm, 900–1.050 mm 4) |

| Folding box dimensions (L × B × H) | min 30 x 40 x 15 mm, max 120 x 200 x 100 mm 5) |

| Weight / with ramper evident technology | approx. 400 kg / approx. 600 kg |

FOOTNOTES:

- By limiting the speed of the traditional coding systems to 60 m/min at a resolution of 300 dpi

- Dependent on product from, product behavior, transport speed, and local conditions

- Water jet from above

- Other working heights by request

- Other carton dimensions on request

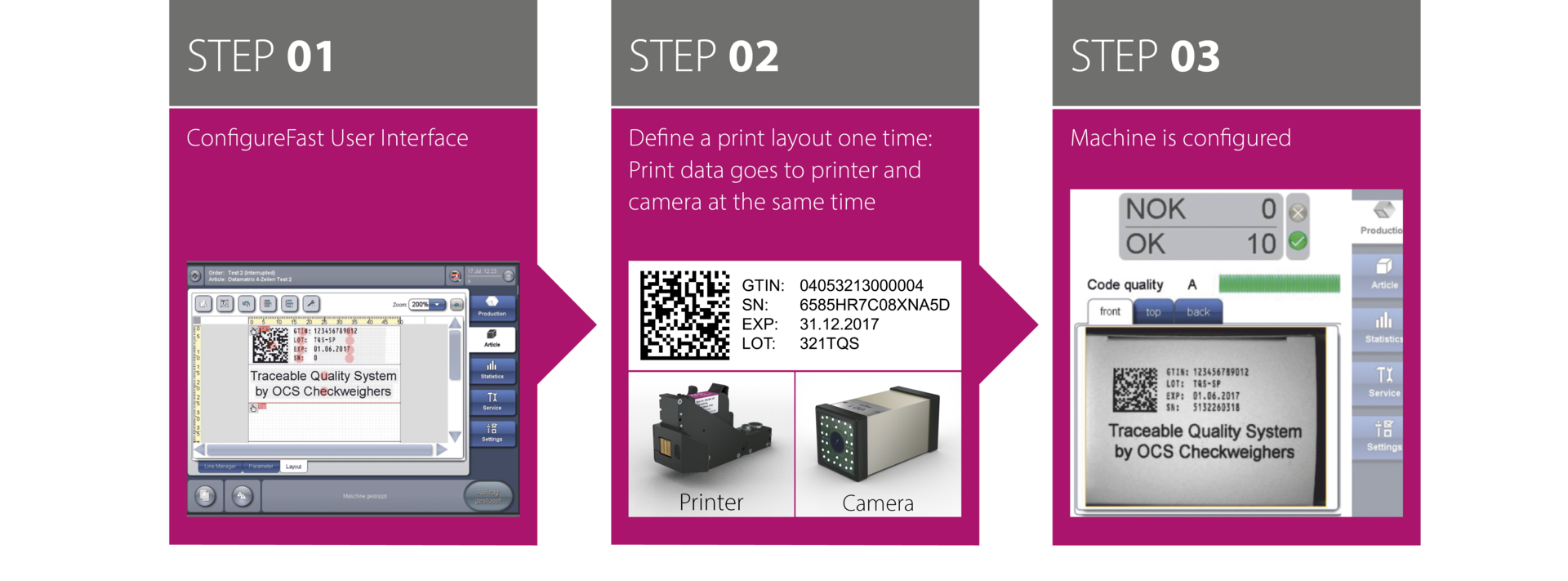

INTUITIVE CONFIGURATION SOFTWARE

Cofigure Fast controls the transport system, coding unit, camera, checkweigher and labeller all from a single HMI interface. As an operator this means easy, quick set-up translatimg into short changeover times on product change. Work with one interface instead of multiple seperate HMI’s, plus no product training is required for your camera system when introdcing new products.

SUPPORT FOR STANDARDIZATION

Active members in both the GS1 Germany and Open SCS Working groups with a focus to support standadrdization promoting open and flexible systems ensuring choice for clients.

GLOBAL SERVICE

Dependable expert services, customized to your needs. Factory trained technicians, along with remote service capabilities, we will help you to design a plan that best serves your needs.